Ever-tightening environmental restrictions are placing new demands on business and the fabric filtration industry. Fortunately, the answer to tomorrow’s tighter restrictions can be found today in Micro Denier felt technology.

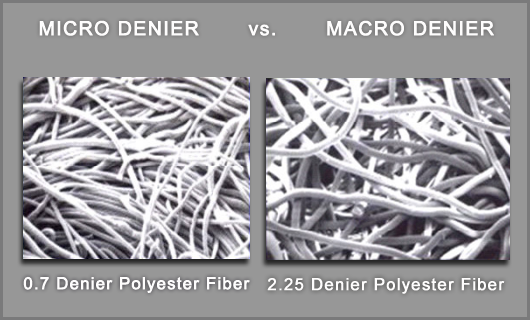

These felts are engineered with micro-denier fibers which provide the highest filtration efficiency of any non-membrane filter felt. Micro Denier felts are produced with fibers that provide more surface area than traditional size fibers.

Tests run by an independent environmental testing agency show that when compared to the industry testing agency show that – when compared to the industry standard – Micro Denier Polyester Felt,

1. Improved efficiency 67% (ASTM D6830-02; PM 2.5)

2. Lowered ∆P 45%

3. Required 46% fewer pulses to maintain a set ∆P

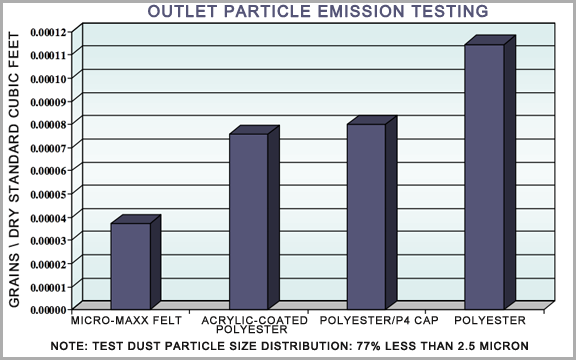

PM 2.5 EFFICIENCY TESTING

PM 2.5 Efficiency tests compared Micro Denier to polyester felt, acrylic coated polyester felt and polyester felt with a P-84 cap. Micro Denier was 53% more efficient than polyester felt with a P-84 cap, which has for several years had been the “high efficiency” felt of choice for many difficult applications. Micro Denier felt means lower operating costs – as well as higher filter efficiency.

It is the increased surface area of the Micro Denier fibers that keep the dust particles on the surface of a the filter bag. The improvement in surface filtration also provides excellent cake release in addition to the excellent filtration efficiency. The improved cake release and lower ∆P leads to lower fan horsepower requirements and fewer pulses to maintain production demand. Less cleaning means reduced consumption of compressed air. Therefore, the end result of switching from regular felt bags to bags made with Micro Denier felt is lower operating costs and increased profits.

AVAILABLE FIBERS FOR MICRO-DENIER FELT

- ARAMID (NOMEX)

- HOMOPOLYMER ACRYLIC

- KERMEL TECH PPS (RYTON)

- P-84

- POLYESTER

- PPS (RYTON