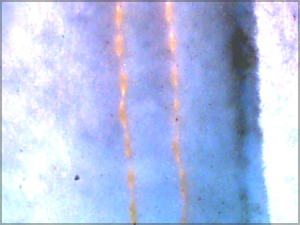

TRIPLE-NEEDLE SEAM BAGS

Triple-needle stitching is the gold-standard method of manufacturing a filter bag. When referring to a triple-needle bag, we are referring to the horizontal seam along the filter bag. The machine uses three needles and tubes (sews) the filter with three separate lines. Triple-needle machines use a chain stitch technology that requires six rolls of thread to complete the operation. The ends of a filter bag are usually either double-needle stitched, or surged in place.

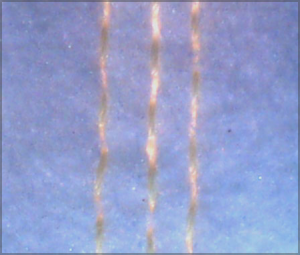

DOUBLE-NEEDLE SEAM BAGS

Double-needle bags are just as implied. The horizontal filter bag seam is sewn with a two-needle machine which uses a chain stitch. A double needle bag seam is still acceptable and will hold up to most applications, but does not offer the extra security of a triple-needle stitched filter bag. Filter bags constructed using double-needle machines are typically small orders and are for specific custom filters.

WELDED-SEAM BAGS

Welded-seam filters have been used for the past six or seven years. These filters are produced by directly melting the fabric with hot air, then running a pressure roller over the seam. The molten fabric bonds together firmly as the roller passes over the vertical seam Welded-seam filters are slightly less expensive to produce and are most common in a collector sent from an O.E.M. to reduce cost.

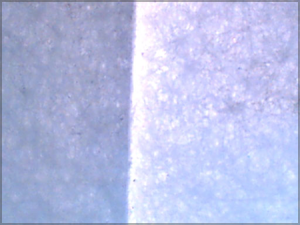

It is notable that a welded seam bag will not have the needle marks present in the media. Most filter bags are not affected by the sewing machine needle marks. Welded seams have become very common in liquid filter bags.

Welded-seam “air” filters are not as widely accepted as triple-needle filter bags. Notice there are no stitch marks on the seam.