PULSE-JET FILTER BAGS

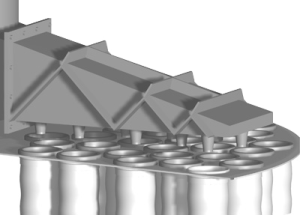

FilterPro manufactures pulse-jet and plenum pulse-jet filter bags. A pulse-jet collector uses a pulse of air to clean the filter bags while they are on line. The cleaning system usually consists of compressed air, a solenoid valve, a  diaphragm valve, and blow pipes. Pulse-jet collectors have become very common and are an efficient way to remove accumulated dust on a filter bag. Filter bags are one of two distinct styles, either top-load (snap band, or flange) filter, or a bottom load (raw edge) filter.

diaphragm valve, and blow pipes. Pulse-jet collectors have become very common and are an efficient way to remove accumulated dust on a filter bag. Filter bags are one of two distinct styles, either top-load (snap band, or flange) filter, or a bottom load (raw edge) filter.

Typically, a top load bag will have a snap band, flange, raw edge, or ring (metal or buna rubber) on the top end of the filter. The bottom of the filter has either a disk sewn into the end, or can be sewn flat. Pulse-jet filters are most commonly made of 16 ounce needled-felt. Multiple materials (medias) and options, such as ground wire to meet the dust collector requirements, are available for a pulse-jet filter bag.

SHAKER BAGS

Shaker collectors clean the filter using mechanical energy or motion. A shaker will normally have the open

end of the filter on the collector floor and will be attached to a mechanism that literally shakes the filter bag clean.

Shaker bags may have a snap band, raw edge, hem, or cord style configuration on the open side of the filter bag. The closed end of the filter will have a way to hang it from the shaker mechanism. This may be a strap, loop, grommet, or A-hanger. Filter bags are commonly made from woven polyester or polyester needled-felt (10 or 12 ounce). Anti-collapse rings may be used to hold the bags open for maximum cleaning, and air flow.

FilterPro’s team will help with media that will provide you the performance you require.

REVERSE AIR FILTER BAGS

A reverse air dust collector uses a sweep that blows air into the filter’s clean side, reversing the air flow and cleaning the filter bags. Common top designs are; compression band, strap top, loop top, cord top cuff and grommet top bags. Bottom types include; raw edge, cuffed, compression band or snap band cuff. Anti-collapse rings may be used to hold the bags open for maximum cleaning, and air flow.

CUSTOM FILTER BAGS

We can manufacture filter or chutes for any need or application – from filters made to fit over 55 gallon drums to a filter that has various snouts and inlets. FilterPro has a solution for all your custom needs.

OEM CAPABILITY

Standard Filter manufactures filter bags for any application, including custom filter bags.

Some examples include:

| Aaron Aerodyne Aeropulse Aget Airtrol Air Conveying Air Sentry Allen Sherman Hoff Amerex American Air Filter American Std Argo Blower Astec Industries BACT Engineering Balox Bahnson Hawley-Norblo-Envirotech Barber-Green Baumco Belco Bituma Construction BMG Brandt Engineering Buell/Norblo Buffalo Forge Buhler-Miag Carter-Day Cedar Rapids |

Clark’s Sheet Metal Clemco Mfg. CMI C-E DCE Volkes Dustex Dusty Dustless/Griffin Env. Dynamic Air Eastern Control Systems Emtrol Environmental Elements Esstee Mfg. Co. Evo ExCel Air Fabrics Filters N.W. Farr Filter Corp. Flakt Flex-Kleen Fulter GMD Engineered Systems GenTec General Resource George Rolfes |

Green Steel Guzzler Hoffman ICA/Ecolair ICM Intensifilter Interel/Luhr Johnson March Kice Kleissler Lear Siegler Lamson Mac Equipment McCarter Mikropul Moldau Murphy-Rodgers Norblo Pangbom/Carborundum Parsons Peabody Process System Percy Todd Mfg. Perlite Pneumafil Premier Pneumatics Procedair Ind. Rayjet/CEA |

Rees Research-Cottrel Ruemelin Mfg. Saunco Scientific Dust Coll. Semco/Keystone Intl. Seneca Spahr Staclean Standard Havens Standard Metals Stansteel Steelcraft Tarmac Tech-Air Torit/Donaldson Ultra Industries US Air United Air Specialist United Conveyor WW Sly Western Pneumatics Westinghouse Wheelabrator-Frye Wiedenmann Young Ind. Zero Zurn Air Industires many more.. |